We’ve got a tricky one for you today: a Frigidaire-built Kenmore electric dryer that only runs on heat cycles. If you set it to a timed or auto dry, it runs just fine. But set it to air fluff, and you get nada — no motor rotation, no nothin’. Sounds like a bad timer, right? That was our first thought, too. But like any good tech should, we covered all of our bases before jumping to conclusions, and what we found was much more interesting…

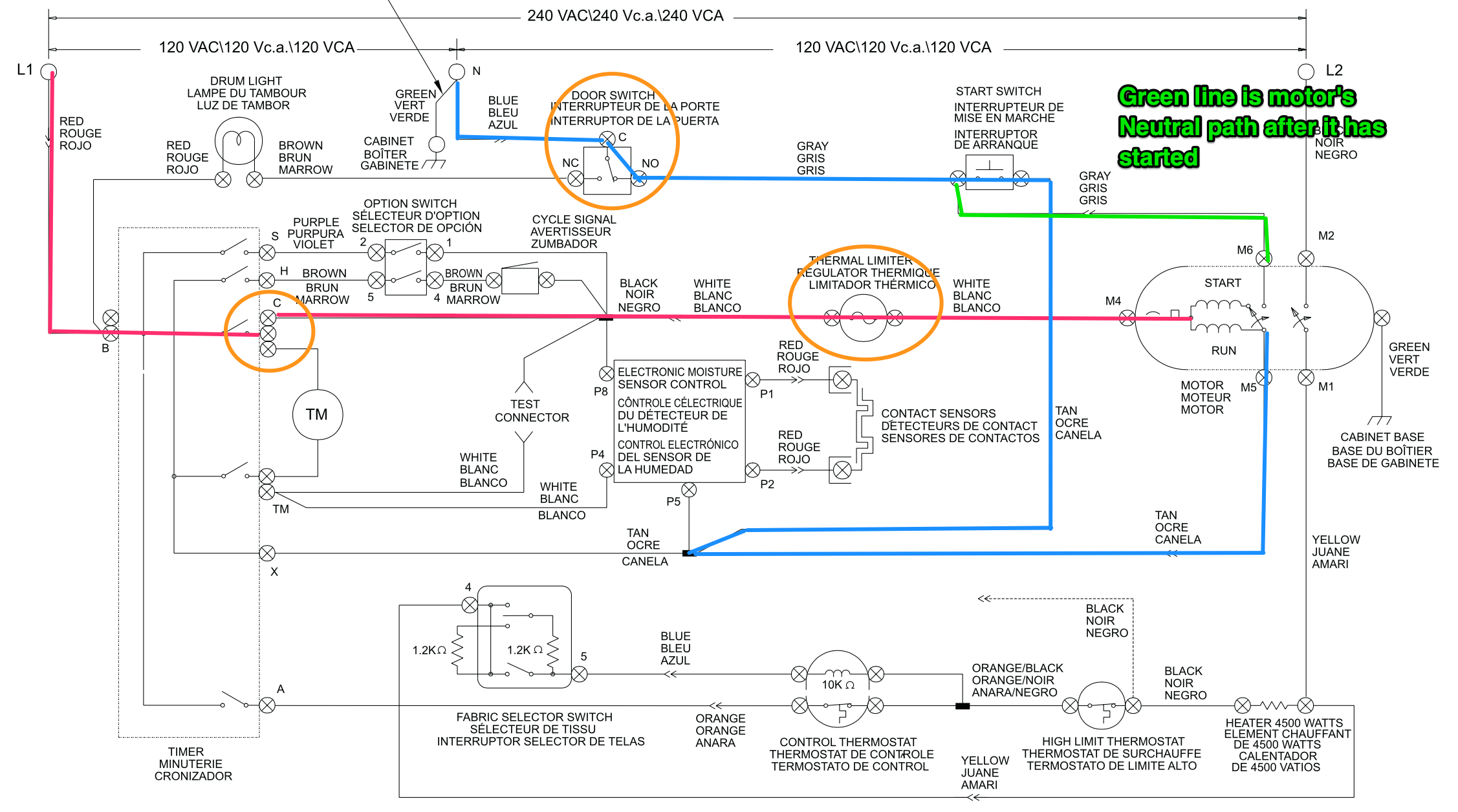

We’ll start by analyzing the circuit of the motor, since that’s the LOI — the thing that ain’t doing its thang.

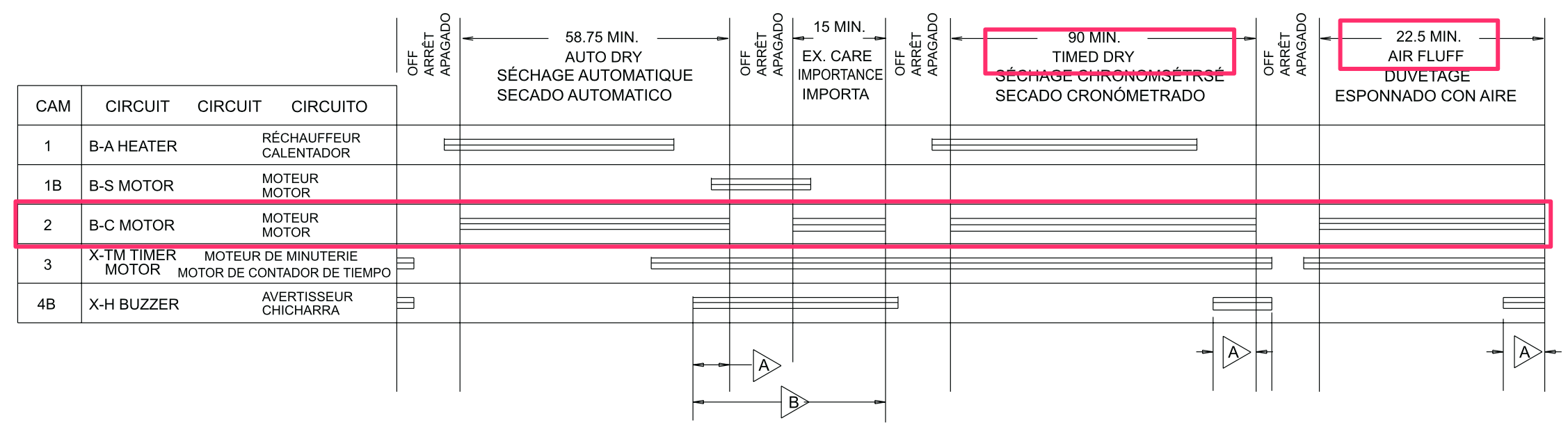

And the timer chart as well, paying special attention to B-C, since those are the contacts that need to close for the motor to run in both timed dry and air fluff.

Looks pretty standard, and what’s more, it looks like B-C really is the only possible culprit. A quick and dirty test that can tell us for sure if B-C is staying open in air fluff would be to run an air fluff cycle, then jump B-C, bypassing the timer. If that makes the motor run, then that would prove it’s a problem with the timer not closing B-C in air fluff.

So what happens when you perform that test in this scenario? Nothing. Jumping B-C makes no difference.

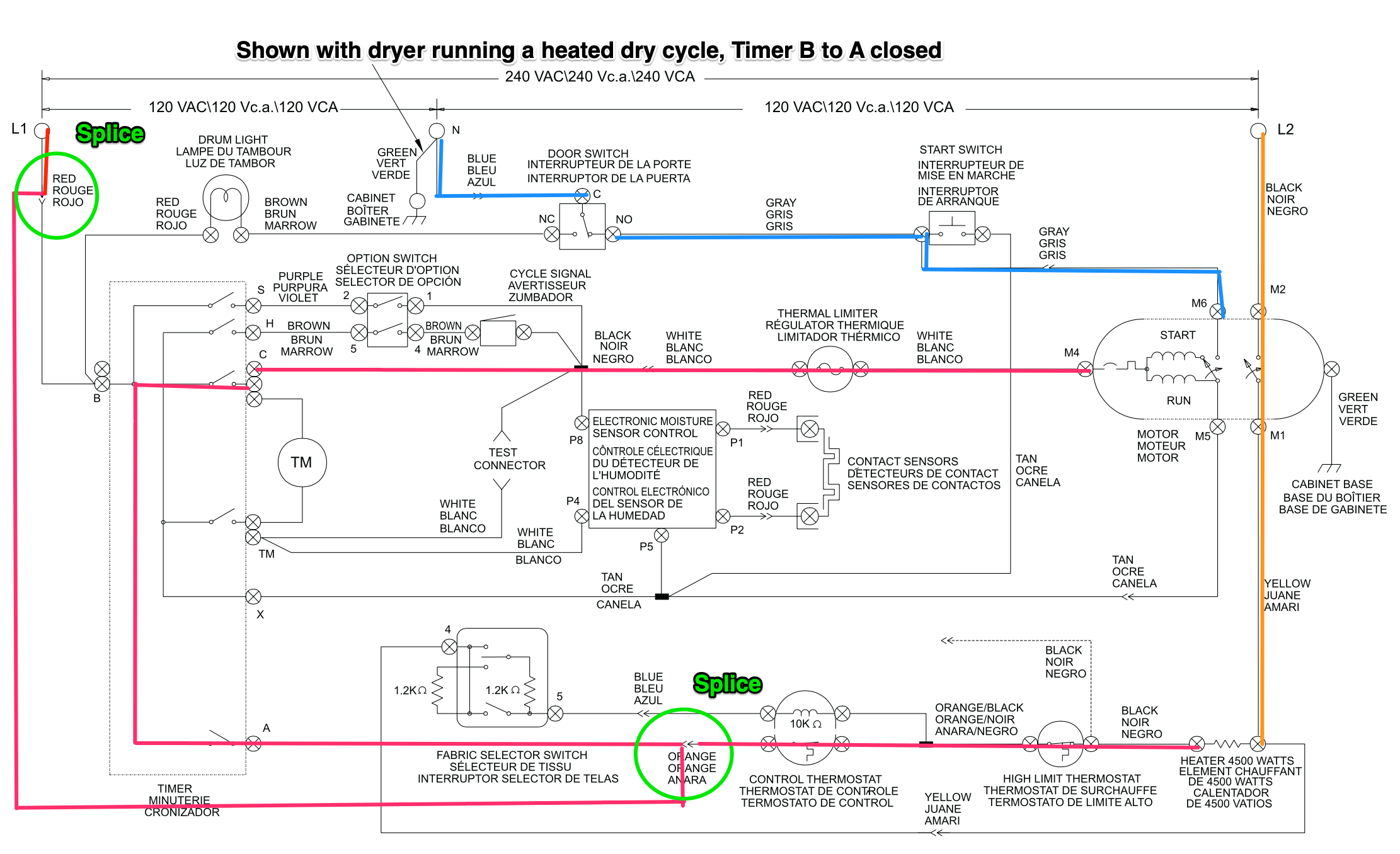

Boy, that’s a real head-scratcher. Fortunately, just as we were at a loss, a new piece of info came to light: a couple of wires had been clipped out of a molex connector and spliced together. Specifically, we’re looking at the red wire going to B on the timer, and the orange wire going to A.

With this new revelation, it all became clear. The red wire and the orange wire had been incorrectly spliced together. Not sure what the implications of that are? Neither were we, until we sat down and sketched it out on a schematic.

And now our problem statement finally makes sense. With this incorrect splice, L1 could only make it to contact C of the timer if contact A was closed, which only happens during a heat cycle.

There we have it — our definitive answer to what caused this problem. No guesswork, no Hail Mary part swaps. Once that splice was corrected, things started working just as they should.

Want to learn to understand circuits and troubleshoot like a pro? Click below to enroll in the online Core Appliance Repair Training course right here at the Master Samurai Tech Academy.